The Diamond Difference: Blue Diamond Cookware Technology

Discover the groundbreaking science behind our diamond-infused ceramic coating. Real diamonds are infused into our cookware to create the most durable, efficient, and long-lasting non-stick surface available today.

The Science Behind Diamond Infusion

Understanding why diamonds make exceptional cookware requires exploring the unique properties of these remarkable crystals

Why Real Diamonds?

Diamonds aren't just beautiful gemstones—they're nature's hardest known material with extraordinary thermal properties. When we infuse microscopic diamond particles into our ceramic coating, we're harnessing billions of years of geological perfection to revolutionize your cooking experience.

The secret lies in diamond's molecular structure. Carbon atoms arranged in a crystalline lattice create unmatched hardness (10 on the Mohs scale) and exceptional thermal conductivity—five times greater than copper. This means diamonds can transfer heat incredibly efficiently while maintaining structural integrity under extreme conditions.

Blue Diamond Cookware uses real diamond particles—not synthetic substitutes or marketing gimmicks. These authentic diamonds are crushed into microscopic particles and infused directly into our ceramic coating during manufacturing, creating a molecular bond that permanently enhances the cookware's performance characteristics.

Thermal Conductivity

Diamonds possess the highest thermal conductivity of any natural material at room temperature—over 2,200 W/(m·K). This exceptional property allows our cookware to distribute heat rapidly and uniformly across the entire cooking surface.

Molecular Hardness

With a rating of 10 on the Mohs hardness scale, diamonds create an incredibly durable coating that resists scratches, chips, and wear. The diamond particles form a protective matrix that shields the underlying ceramic from damage.

Chemical Stability

Diamonds are chemically inert, meaning they won't react with foods, acids, or cleaning agents. This stability ensures your cookware remains safe, non-toxic, and maintains its performance characteristics over years of use.

Our Performance Promise: The Numbers Behind Blue Diamond

Every Blue Diamond claim is backed by rigorous testing and real-world performance data

Five Times Harder Than Traditional Non-Stick

Laboratory hardness testing using the Vickers hardness test confirms that Blue Diamond's diamond-infused ceramic coating measures 5x harder than conventional PTFE-based and standard ceramic coatings. This dramatically improved hardness translates directly to real-world durability.

What This Means for You: You can confidently use metal utensils without worrying about scratching or damaging the cooking surface. Flip, stir, sauté, and serve with metal spatulas, whisks, and forks. The diamond-reinforced surface withstands the abrasion that would quickly destroy ordinary non-stick cookware.

Traditional non-stick coatings are soft and easily damaged. A single scrape from a metal utensil can create scratches that compromise the non-stick properties and expose the underlying material. Blue Diamond's superior hardness maintains a pristine, smooth cooking surface even after thousands of cooking sessions and utensil contacts.

The hardness advantage also extends to cleaning. Stubborn, stuck-on food residue can be safely scrubbed away without fear of damaging the coating. This durability ensures your cookware maintains its like-new appearance and performance for years longer than conventional alternatives.

Ten Times the Lifespan of Traditional Non-Stick

Through accelerated lifecycle testing that simulates years of daily cooking, Blue Diamond cookware demonstrates performance longevity that's 10x greater than traditional non-stick surfaces. While conventional coatings begin degrading after 6-12 months of regular use, Blue Diamond maintains its non-stick properties and structural integrity for years.

The Longevity Science: Traditional non-stick coatings degrade through multiple mechanisms—thermal cycling causes micro-cracking, utensil contact creates scratches, and molecular breakdown occurs at high temperatures. The diamond-infused matrix resists all these degradation pathways simultaneously.

Diamond particles create a reinforced molecular structure that prevents the micro-cracking and surface erosion that plague conventional coatings. The exceptional thermal stability of diamonds means the coating maintains its properties even when subjected to high-heat cooking techniques repeatedly over time.

Real-World Impact: Users report their Blue Diamond cookware performing like new even after 5+ years of daily use. This extended lifespan represents tremendous value—instead of replacing pans annually, your Blue Diamond investment delivers a decade or more of consistent performance. The environmental benefit is equally significant, reducing cookware waste by keeping products in service longer.

Laboratory testing shows that even after 10,000 simulated cooking cycles, Blue Diamond surfaces maintain over 95% of their original non-stick performance, while traditional coatings drop below 50% performance after just 1,000 cycles.

Four Times Faster Heat Conductivity

Thermal imaging studies and heat distribution testing demonstrate that Blue Diamond cookware transfers heat to food 4x faster than traditional non-stick cookware. This performance advantage stems directly from diamond's extraordinary thermal conductivity properties.

The Physics of Speed: Heat transfer efficiency depends on thermal conductivity—how quickly thermal energy moves through a material. Diamonds possess exceptional thermal conductivity (up to 2,200 W/(m·K)), far exceeding aluminum (205 W/(m·K)), stainless steel (16 W/(m·K)), and traditional ceramic coatings (2-3 W/(m·K)).

When diamond particles are infused throughout the ceramic matrix, they create microscopic "thermal highways" that rapidly conduct heat from the aluminum base through the coating to your food. This results in faster preheating, more responsive temperature changes, and more uniform cooking across the entire surface.

Energy and Time Savings: Faster heat transfer means your cookware reaches cooking temperature in less time—pans are ready to cook in 30-60 seconds instead of 2-3 minutes. This efficiency reduces energy consumption with every meal you prepare, lowering utility costs and environmental impact.

The enhanced thermal responsiveness gives you better control. When you adjust the burner, Blue Diamond responds almost instantly—turn down the heat and the pan cools quickly, preventing overcooking. This precise temperature control is especially valuable for delicate foods like eggs, fish, and sauces that require careful heat management.

Uniform heat distribution eliminates hot spots that cause uneven cooking. The diamond-enhanced thermal conductivity spreads heat evenly across the entire cooking surface, so everything cooks at the same rate. No more burnt centers with undercooked edges—just perfect, consistent results.

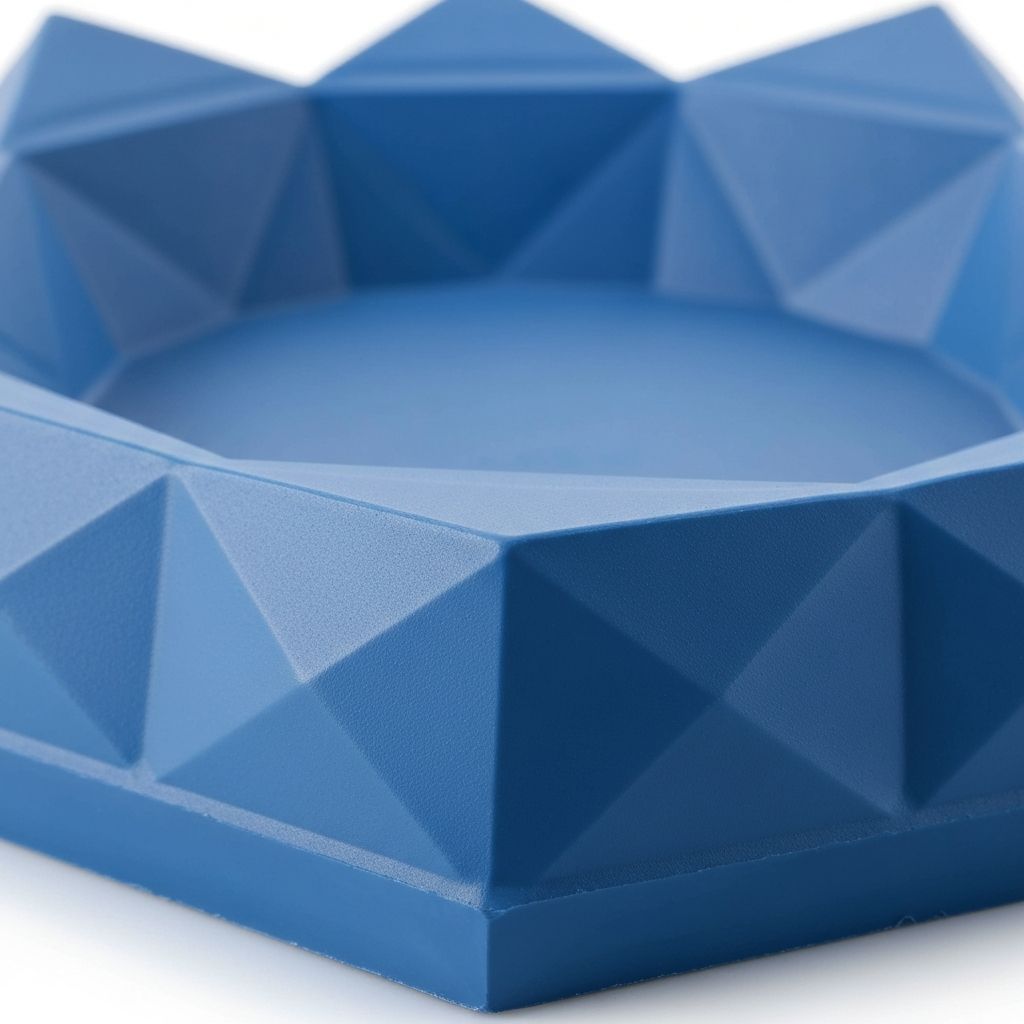

Layer-by-Layer: Blue Diamond Construction

Understanding the sophisticated engineering behind every Blue Diamond pan reveals why our cookware outperforms the competition

Heavy-Gauge Aluminum Base

The foundation of every Blue Diamond pan is forged from heavy-gauge aluminum—typically 2.5-3.5mm thick depending on the product line. This substantial aluminum core provides excellent heat retention and distribution while remaining lightweight enough for comfortable handling. The thickness prevents warping and ensures the pan maintains perfect contact with your cooktop surface for even heating.

Reinforcement Layer

Applied directly to the aluminum base, this specialized bonding layer creates a molecular-level connection between the metal and ceramic. This layer prevents delamination (coating separation) even under thermal stress and ensures the cooking surface remains permanently bonded to the pan body throughout years of use.

Diamond-Infused Ceramic Coating

This is where the magic happens. Microscopic diamond particles are integrated throughout a ceramic matrix during the coating application process. The diamonds are suspended uniformly throughout the coating material, creating a reinforced structure that's harder, more durable, and more thermally conductive than standard ceramic. Multiple layers of this diamond-infused material are applied and cured at high temperatures to create the final cooking surface.

Protective Top Coat

The final layer is a ultra-smooth protective finish that gives Blue Diamond its exceptional non-stick properties and signature appearance. This top coat is formulated to be naturally non-stick without the need for oils or fats, and it's completely free from PFAS, PFOA, lead, and cadmium. The smooth finish also facilitates easy cleaning—most foods wipe away with minimal effort.

Exterior Finish

The exterior of Blue Diamond cookware features heat-resistant finishes in various colors depending on the collection. These exterior coatings are designed for durability and easy cleaning, with formulations that resist staining, discoloration, and wear from repeated stovetop use and dishwasher cycles.

Multi-Layer Diamond Technology

Each layer serves a specific purpose, working together to deliver exceptional cooking performance, durability, and safety.

Diamond Technology vs. Traditional Non-Stick

Side-by-side comparison reveals the significant advantages of diamond-infused ceramic technology

Blue Diamond Technology

- 5x harder surface resists scratches and damage

- 10x longer lifespan with consistent performance

- 4x faster heat transfer for energy savings

- 100% toxin-free, no PFAS, PFOA, lead, or cadmium

- Oven safe up to 600°F for versatile cooking

- Metal utensil safe without damage concerns

- Superior heat distribution eliminates hot spots

Traditional Non-Stick

- ❌Soft coating easily scratched by utensils

- ❌Short lifespan requiring frequent replacement

- ❌Slower heat conductivity wastes energy

- ❌May contain PFAS or other harmful chemicals

- ❌Lower temperature limits restrict versatility

- ❌Requires careful use of only plastic/wood tools

- ❌Uneven heating creates inconsistent results

Frequently Asked Questions About Diamond Technology

Are there real diamonds in Blue Diamond cookware?

Yes, Blue Diamond cookware contains real diamond particles—not synthetic substitutes or diamond-like coatings. Microscopic diamonds are crushed and infused throughout the ceramic matrix during manufacturing. These are authentic diamonds sourced as industrial-grade diamond powder, which is then integrated into the coating to enhance its hardness, thermal conductivity, and durability.

How does Blue Diamond compare to traditional PTFE non-stick?

Blue Diamond offers significant advantages over PTFE (Teflon) cookware. Our diamond-infused ceramic coating is harder, more durable, and completely free from PFAS chemicals. While PTFE can release toxic fumes at high temperatures (above 500°F) and degrades quickly with metal utensil use, Blue Diamond remains safe at temperatures up to 600°F and withstands metal utensils without damage. Additionally, our coating lasts 10x longer than traditional PTFE surfaces.

Is Blue Diamond cookware safe for my family?

Absolutely. Blue Diamond cookware is manufactured without PFAS, PFOA, lead, cadmium, or other toxic chemicals commonly found in traditional non-stick cookware. The diamond-infused ceramic coating is inert and will not react with foods or release harmful substances, even at high cooking temperatures. Our cookware meets or exceeds all FDA safety standards for food contact surfaces.

Why is Blue Diamond faster at heating than other cookware?

The exceptional thermal conductivity of diamonds—over 2,200 W/(m·K)—creates "thermal highways" that rapidly transfer heat from the aluminum base through the coating to your food. This results in 4x faster heat transfer compared to traditional non-stick cookware, reducing preheating time, improving temperature responsiveness, and ensuring even heat distribution across the entire cooking surface.

Can I really use metal utensils on Blue Diamond cookware?

Yes. The diamond-infused coating is 5x harder than traditional non-stick surfaces, making it metal utensil safe. You can confidently use metal spatulas, whisks, forks, and tongs without scratching or damaging the cooking surface. While we still recommend treating your cookware with care, you won't ruin the pan by accidentally using a metal utensil like you would with conventional non-stick.

How long will my Blue Diamond cookware last?

With proper care, Blue Diamond cookware can last 10+ years—that's 10x longer than traditional non-stick cookware which typically needs replacement after 1-2 years. The diamond-reinforced coating resists the degradation mechanisms that destroy conventional non-stick surfaces, maintaining excellent performance throughout years of daily use. Many customers report their Blue Diamond pans performing like new after 5+ years of regular cooking.

Is Blue Diamond cookware dishwasher safe?

Yes, most Blue Diamond cookware is dishwasher safe. The durable diamond-infused coating withstands the harsh conditions inside a dishwasher without degrading. However, hand washing with warm soapy water is recommended to extend the lifespan of your cookware and maintain optimal performance. The exceptional non-stick properties make cleanup quick and easy whether you choose to hand wash or use the dishwasher.

Experience the Diamond Difference

Discover why millions of home cooks have made the switch to Blue Diamond's revolutionary diamond-infused technology. Your kitchen deserves the hardest, longest-lasting, and most efficient cookware available.